Teletim, a Romanian furniture manufacturer specializing in high-quality metal beds, was founded in 1990 by Alinda Neagu's parents, combining their engineering expertise with entrepreneurial vision.

"My mother, a mechanical engineer, left academia to open a metalworking workshop," recalls Alinda. "My father, an electronics engineer, joined her, and together they started producing antennas for radio taxi stations." At first, the workshop had just two employees.

The first metal bed came in 2000, built for the family home. Guests visiting from the United States were so impressed that they requested their own, sparking Teletim's bed production. In 2006, the company received its first major order: 10,000 single beds for a government emergency-response program. Today, Teletim is a modern factory equipped with laser and MIG/MAG welding robots, CNC tube-bending machines, and a powder-coating line.

© Teletim

© Teletim

At the right Alinda Neagu with her mother Magda and a business visitor.

Why Metal Furniture?

Alinda explains that metal furniture was a natural evolution of her family's technical background. "My mother worked on industrial robots during the communist era. Building her own production line was the next step. And even though I studied law, I grew up immersed in the technical world." Family trips to international furniture fairs also influenced her design perspective.

Teletim is the only fully Romanian-owned company producing metal beds in large series based on standardized models. While its main competition comes from China and Turkey, the company distinguishes itself with simpler, cleaner, and more refined designs. "Our visibility isn't yet at the level it should be," Alinda notes, "but our products speak for themselves."

Innovation: Modular slatted bed frames

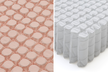

A trade fair in Birmingham revealed a design challenge: Teletim's beds would struggle to fit through narrow London staircases. "That experience pushed us to redesign all our beds so the slatted frame could be fully modular and delivered flat-packed," says Alinda.

Achieving this required laser-precision cutting and a new production line. "My mother innovated the assembly method, and today our beds are as rigid as welded systems, mechanically tested to 237 kg. With the new pallet configuration, we can now load 45 bed frames per pallet, significantly optimizing transportation costs."

© Teletim

© Teletim

Challenges and opportunities

Entering international markets remains a challenge due to Europe's dependence on Chinese imports. "We have to explain the advantages of sourcing from Romania: shorter supply chains, faster delivery, and keeping value within the community," she explains.

Currently, Teletim focuses on promoting its innovative products and educating distributors about sustainable, traceable sourcing. Looking ahead, Alinda envisions the company as a major supplier of metal beds across Europe, building long-term partnerships grounded in quality and reliability.

Looking to the future

Beyond production, Teletim aims to inspire the next generation. "We want young people in metal furniture production to innovate continuously. Metal furniture should not be seen as low-budget; it's a field where quality, design, and durability truly shine," Alinda concludes.

More information:

Teletim

[email protected]

magdadesign.ro